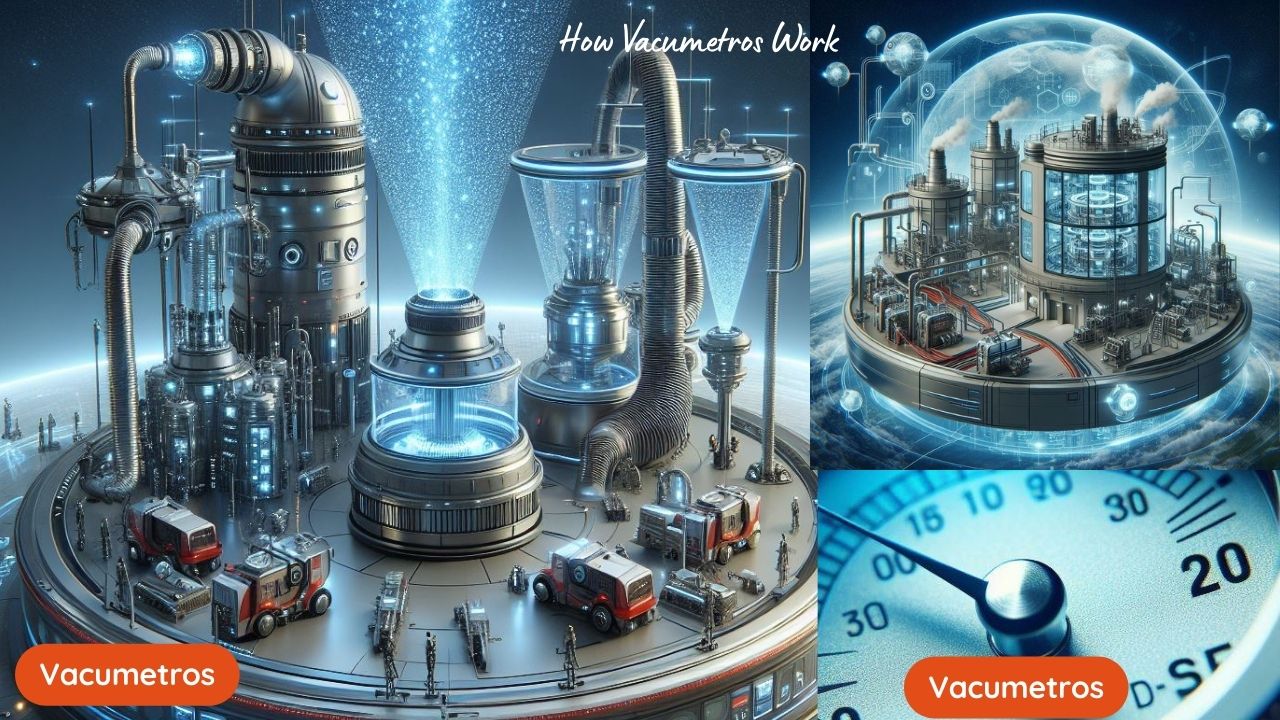

Introduction to Vacumetros

Vacumetros, an essential tool in the realm of vacuum technology, play a pivotal role in measuring and analyzing vacuum levels in various industrial and scientific applications. From manufacturing processes to research laboratories, vacumetros enable precise monitoring and control of vacuum systems, ensuring optimal performance and efficiency.

Understanding the Functionality of Vacumetros

Vacumetros operate on the principle of measuring the pressure differential between a reference pressure and the vacuum under analysis. By converting pressure readings into measurable units, vacumetros provide valuable insights into the performance and integrity of vacuum systems, helping engineers and technicians make informed decisions and adjustments.

Applications of Vacumetros in Different Industries

Vacumetros find extensive use across diverse industries, including semiconductor manufacturing, aerospace, pharmaceuticals, and automotive. In semiconductor fabrication, vacumetros play a critical role in maintaining ultra-high vacuum conditions essential for precise etching and deposition processes. Similarly, in aerospace applications, it ensure the integrity and reliability of vacuum chambers used for testing and simulating space conditions.

Types of Vacumetros and Their Features

It comes in various types and configurations, each tailored to specific applications and performance requirements. Analog it feature traditional dial gauges for pressure measurement, providing simplicity and reliability in operation. Digital it, on the other hand, offer advanced features such as digital displays, data logging capabilities, and remote monitoring options, enhancing precision and versatility in vacuum system analysis.

Advancements in Vacumetros Technology

Advancements in sensor technology, data processing algorithms, and connectivity options have propelled the evolution of it, enabling greater accuracy, reliability, and functionality. Modern it integrate features such as automatic calibration, pressure trend analysis, and compatibility with IoT platforms, empowering users to optimize vacuum system performance and minimize downtime.

Benefits of Using Vacumetros

The use of vacumetros offers numerous benefits to industries and research institutions alike. By providing real-time feedback on vacuum levels, It help prevent equipment damage, improve process efficiency, and reduce product defects. Moreover, it facilitate predictive maintenance strategies, enabling proactive identification and resolution of potential issues before they escalate into costly failures.

Also read this" Depondo: Exploring Its Functions and Significance "

Conclusion

In conclusion, It stand as indispensable tools in the field of vacuum technology, enabling precise measurement and control of vacuum levels in a wide range of applications. Their versatility, accuracy, and reliability make them essential assets for industries seeking to maintain optimal performance and efficiency in vacuum systems. As technology continues to evolve, it will remain at the forefront of innovation, driving advancements in manufacturing, research, and exploration.

(FAQs):

1. What are the key factors to consider when selecting a vacumetro for a specific application?

When selecting a it, key factors to consider include the desired pressure range, accuracy requirements, response time, compatibility with existing equipment, and ease of integration into the vacuum system.

2. How often should vacumetros be calibrated to maintain accuracy?

It should be calibrated regularly according to manufacturer recommendations and industry standards. Typically, calibration intervals range from six months to one year, depending on usage frequency, environmental conditions, and regulatory requirements. Regular calibration ensures that it maintain their accuracy and reliability over time, providing consistent and trustworthy measurements in vacuum system operations.

3. Can vacumetros be used in hazardous or corrosive environments?

Yes, it designed for hazardous or corrosive environments are available, featuring rugged construction, corrosion-resistant materials, and explosion-proof certifications. These specialized It are suitable for applications in chemical processing, petrochemical, and industrial manufacturing environments.

4. How do vacumetros help optimize vacuum system performance and efficiency?

It provide real-time feedback on vacuum levels, allowing operators to monitor system performance, identify leaks or inefficiencies, and optimize process parameters accordingly. By maintaining optimal vacuum levels, it help maximize productivity, reduce energy consumption, and prolong equipment lifespan.

5. Are there any special considerations for installing and maintaining vacumetros?

When installing and maintaining it, it is essential to follow manufacturer guidelines and best practices to ensure proper operation and longevity. This includes proper mounting, calibration, and periodic inspection of it components, as well as regular cleaning and maintenance to prevent contamination and deterioration.